Views: 19 Author: Site Editor Publish Time: 2020-08-24 Origin: Site

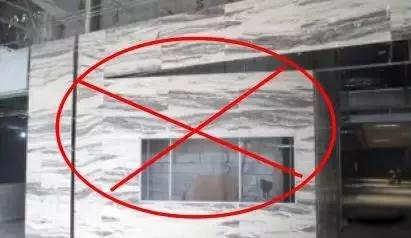

Improper closing of stone and door frame

◆Common problems

The uneven surface (or rough surface) of the wall produces pores at the junction of the stone and other materials

◆Cause analysis

1. Planning and drawing are not in place, and the order size is deviated.

2. The correct technical explanation of the team has not been made, and the installation sequence has been reversed.

◆Precautions

1. Drawings must be deepened in place, and the on-site line setting should consider detailed closing;

2. When placing an order on the line, consider having a smooth surface. Install the light panel at the mouth of the rough surface stone first, and then install the uneven surface (floss surface) stone. At the same time pay attention to control the verticality, flatness and size deviation. You can also consider leaving the concave-convex surface (or rough surface) stone with craft grooves for cutting.

Wall marble texture is messy

◆Common problems

Stone textures with strong patterns and textures are obviously not connected

The whole wall is messy

◆Cause analysis

1. The project department and the stone factory are not in place;

2, the project department has not carried out close follow-up of after-field processing;

3, processing manufacturers have a weak sense of quality in typesetting;

4. Workers have weak installation awareness and fail to follow the typesetting sequence number;

◆Precautions

1. First, you should typeset as a whole, and number the typeset marbles.

2, the marble factory should typesetting and cutting according to the serial number (the company should set up a resident to supervise).

3. The cut marble shall be sent to the project strictly according to the typesetting number, and the workers shall install it strictly according to the number.

The grooved stone is closed with black seams

◆Common problems

There is a large gap when the stone grooved plate is closed with stainless steel and other related materials

Or the presence of other materials to pull the grooved plate causes a cavity in the closing

◆Cause analysis

1, the size of the order placed on the slotted plate is not accurate;

2. The construction and installation of on-site workers are not in place, and the cutting is not good;

◆Precautions

1. When placing an order, the management personnel must conduct an on-site review, first perform accurate line-out, and then accurately place the order according to the actual size of the stone, so as to achieve the precise size of the order.

2. The length of stainless steel can be lengthened appropriately during the processing of stainless steel, and the corners can be cut on the spot to avoid the shortage of stainless steel length caused by reserved spaces during stone construction.

3. When deepening, there is a process groove at the closing, and the closing of the grooved plate is made into a plane, and the size should be uniform. The stainless steel edge is 2-3 mm higher than the stone to ensure a perfect finish.